How expanded metal is made

Expanded metal is made by slitting and stretching sheet in specialized machines—without welded joints or woven wires. The process creates mesh openings with high strength thanks to the angled strands and integral bonds.

From 1 m² of sheet, we can produce 1–15 m² of expanded metal, depending on mesh opening and pitch (step width). Expanded metal is far more material-efficient than perforated sheet, where scrap losses can reach 70–80%.

Expanded metal can be manufactured in many different materials

We manufacture expanded metal in steel, aluminium, copper, nickel, titanium, and stainless steel. We also expand polyethylene using the same method. When the expanded metal is flattened (plan-rolled), it returns to the original sheet thickness but with slightly lower load-bearing capacity and slip resistance.

We can cut expanded metal to size and to shape. We also collaborate with subcontractors for bending/forming, frame assembly, and surface finishing.

The manufacturing process consists of six steps

- Manufacturing: Expanded metal is produced by slitting and stretching sheet metal, creating strong meshes without welded joints or woven wires.

- Material efficiency: From 1 m² of sheet, we can produce 1–15 m² of expanded metal depending on mesh opening and pitch. Expanded metal is far more material-efficient than perforated sheet, where scrap losses can reach 70–80%.

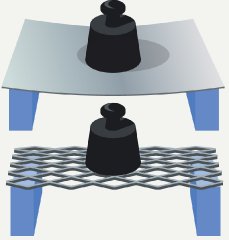

- Flattening: When flattened, expanded metal returns to the original sheet thickness but with slightly reduced load-bearing capacity and slip resistance.